Plastics industry (pipe extrusion, film extrusion blowing, technologies of injection molding, thermoforming)

DUCALCIT the importance of calcium carbonate in various industries with particular reference to the use of calcium carbonate as a filler in the polyvinyl chloride (PVC) industry. Of all fillers used in the PVC processing industry, 80% are calcium carbonate type fillers. Fillers are used in order to improve the various mechanical properties of polymers such as: tensile and break properties, density, hardness, thermal stability, viscosity and more. The latest directions of industrial development as well as the demands of the processing industry for the highest quality carbonate fillers have influenced the introduction of the surface modification process of limestone or calcite, which is the basic constituent of finely micronized limestone in order to improve its properties.

DUCALEN is an eco-friendly granulator-filler in the form of granules with a high content of selected very fine natural calcium carbonate mixed in the LLDPE slider carrier. DUCALEN is mainly intended as an adjunct for film extrusion blowing, in technologies of injection molding, thermoforming, pipe extrusion, etc.

DUCALEN increases productivity and reduces extrusion pressure, dimensional stability, faster cooling time and shorter injection cycle, increases mechanical properties and lowers the cost of the finished product.

Extremely fine powder obtained by grinding natural calcium carbonate well known by its high chemical purity.

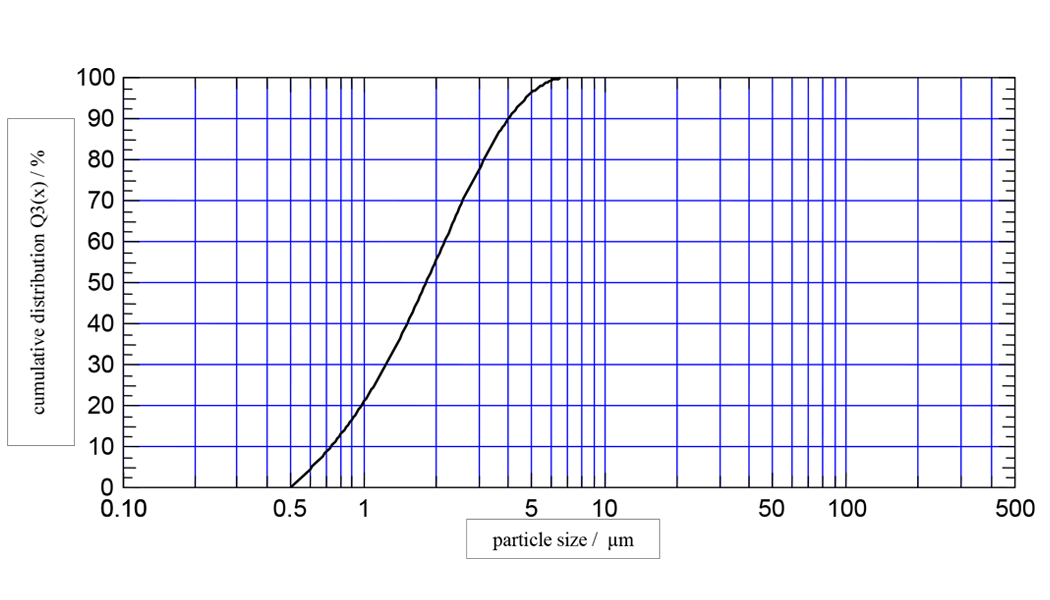

► particle distribution - d50% (1.8 - 2.2 μm)

► particle distribution - d98% (5.7 - 7.5 μm)

Ducalcit 1 - technical data sheet

Extremely fine powder of natural surface finish calcium carbonate. By coating calcium carbonate particles it has hydrophobic characteristics, prevents moisture binding and improves its process characteristics.

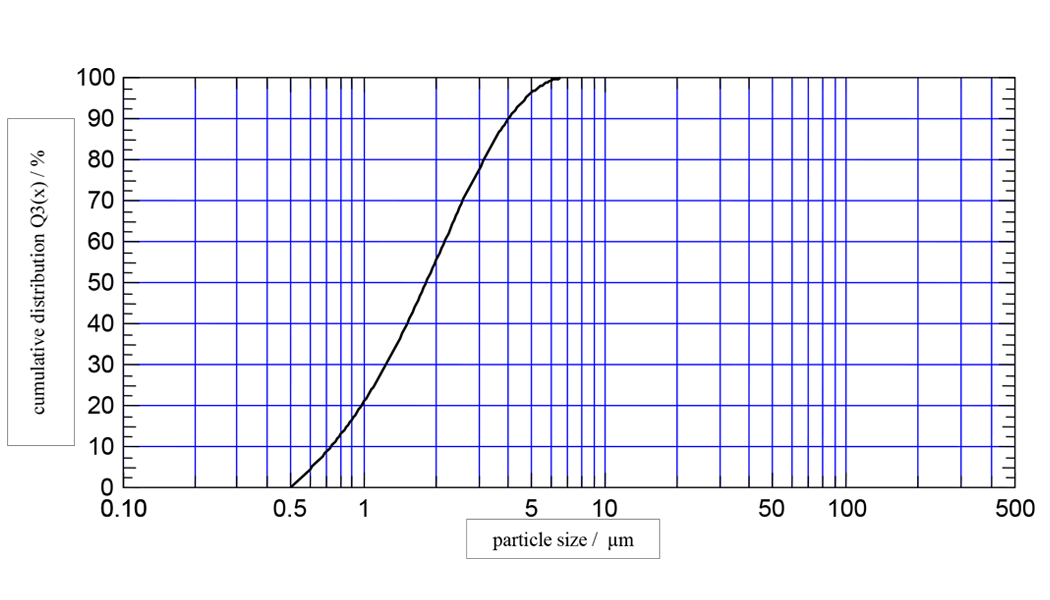

► particle distribution - d50% (1.8 - 2.2 μm)

► particle distribution - d98% (5.7 - 7.5 μm)

Ducalcit 1 SC - technical data sheet

Extremely fine powder obtained by grinding natural calcium carbonate well known by its high chemical purity.

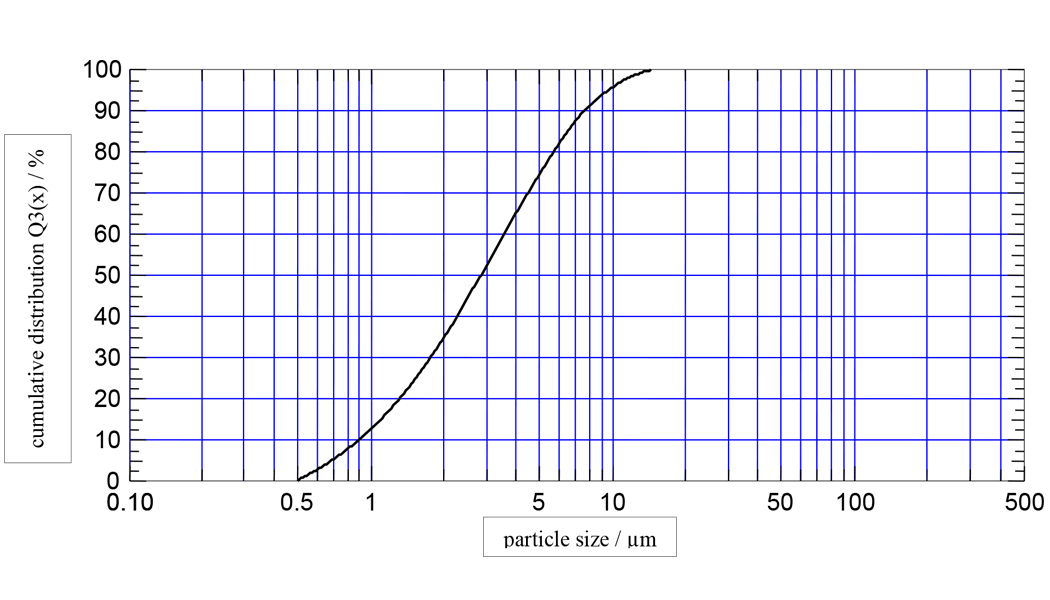

► particle distribution - d50% (2.6 - 3.2 μm)

► particle distribution - d98% (10 - 14 μm)

Ducalcit 2 - technical data sheet

Extremely fine powder of natural surface finish calcium carbonate. By coating calcium carbonate particles it has hydrophobic characteristics, prevents moisture binding and improves its process characteristics.

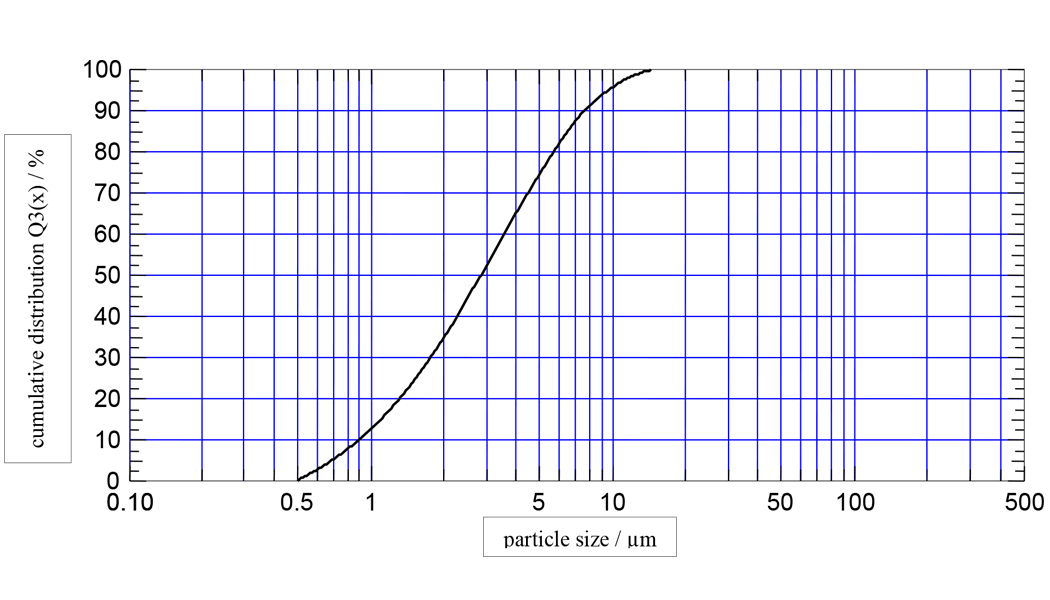

► particle distribution - d50% (2.6 - 3.2 μm)

► particle distribution - d98% (10 - 14 μm)

Ducalcit 2 SC - technical data sheet

DUCALEN 70 is an eco-friendly granulator - filler in the form of granules with high content of very fine natural calcium carbonate mixed in the LLDPE slider carrier. DUCALEN is mainly intended as an adjunct for film extrusion blowing, in technologies of injection molding, thermoforming, pipe extrusion and the like.

DUCALEN 70 can be dosed between 5% and 30% depending on the final product.

Ducalen 70 - technical data sheet

DUCALEN 80 is an eco-friendly granulator - filler in the form of granules with a high content of very fine natural calcium carbonate mixed in the LLDPE slider carrier. DUCALEN is mainly intended as an adjunct for film extrusion blowing, in technologies of injection molding, thermoforming, pipe extrusion and the like.

DUCALEN 80 can be dosed between 5% and 30% depending on the final product.

Ducalen 80 - technical data sheet