Polyurethane industry (sponges and memory foams)

Flexible polyurethane foams are one of the most important classes of cellular plastics used in the production of materials such as sponges, memory foams, cushions, furniture, car lining materials, packaging, footwear, etc. The total consumption of flexible polyurethane foam has been estimated at over 7 million tonnes in 2007, with an average annual growth rate of around 5%.

Generally, flexible polyurethane foam industries use fillers to modify the properties of a material in a certain way to achieve dimensional stability, easy mold withdrawal and service density.

The production cost of flexible polyurethane foam depends significantly on the cost of polyols, which represent the largest percentage of materials used in foam production with the characteristics to induce superior mechanical properties. Suitable fillers that are relatively inexpensive can be introduced into the foam matrix as a substitute for polyol. Influence of CaCO3 filler in a flexible polyurethane foam matrix for dual purposes of achieving sustainable mechanical properties and reducing production costs. The optimal composition of CaCO3 was found to be 20 wt%, which represents a simultaneous decrease in the production cost of 18.54%.

In flexible polyurethane foams, fillers promote an increase in density and compression resistance.

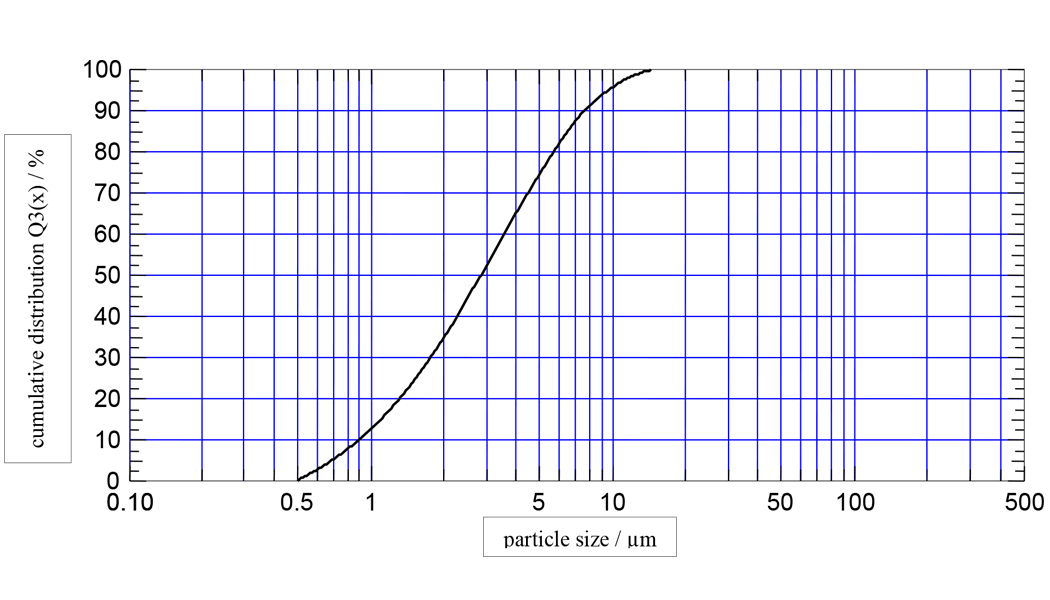

Extremely fine powder obtained by grinding natural calcium carbonate well known by its high chemical purity.

► particle distribution - d50% (2.6 - 3.2 μm)

► particle distribution - d98% (10 - 14 μm)

Ducalcit 2 - technical data sheet

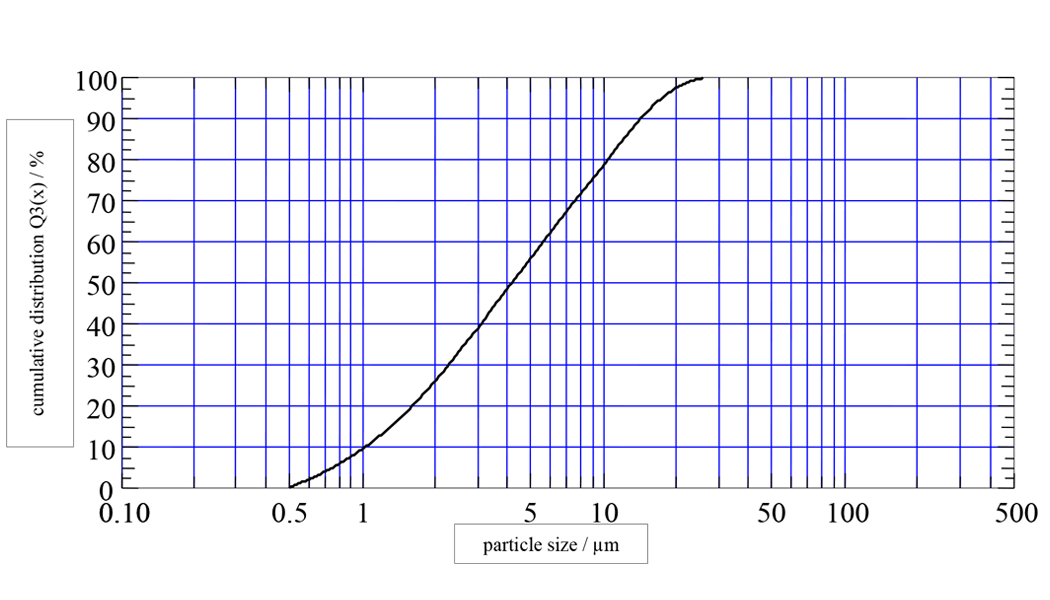

Extremely fine powder obtained by grinding natural calcium carbonate well known by its high chemical purity.

► particle distribution - d50% (2.8 - 4.4 μm)

► particle distribution - d98% (18 - 24 μm)

Ducalcit 5 - technical data sheet